Getting your refrigerator to run without a start relay while you wait for the part

Posted by Admin • Monday, January 19. 2009 • Category: Low Tech HacksIt took me 24 hours to notice that my Maytag top-freezer refrigerator (PTB2454GR) stopped cooling. (OK the puddle on the floor helped me notice). When it started (Saturday morning, I think), there was a click, 10 seconds of buzzing, then silence. This would repeat every 2-3 minutes. I didn't think much of it, thinking it's the ice maker acting weird. What I should have noticed was the complete absence of compressor noise - just the fan. Actually, there wasn't even that noise - it was silent.

I eventually figured out that the start relay (if you can even call it that) needs replacement, but that was not the initial problem - the problem, as it turned out, was one packing peanut. Yeah, one peanut - it got stuck in the Condenser Fan, literally preventing it from running. This in turn probably caused ice buildup, or in some other way increased the compressor load, which in turn finished off the start relay. Frankly, I'm not sure how long the peanut was in there - may have been months, or maybe just a day.

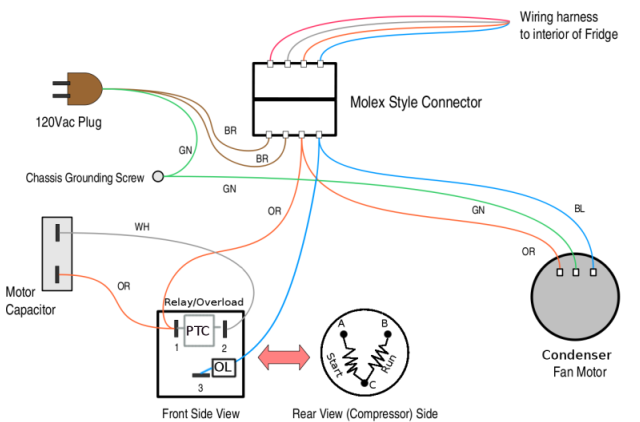

So if you're seeing similar behaviour (see first paragraph), these are the steps to troubleshoot and temporarily remedy the situation (Disclaimer: there is a very good chance of electrocuting yourself in the process, as with any high voltage appliance). I have a little wiring diagram that explains what and why in here as well.

It took me a little while to understand how the fridge even operates.

The Works

So here is a diagram that may help.

- The temperature thermostat up inside the unit turns on power, which goes back down through the molex connector to the orange/blue wires

- Orange + Blue go to both the Condenser Fan, and the compressor control stuff

- Inside the Relay (the white box which looks like a simple connector harness on the compressor) there are two devices of interest: PTC and Overload (OL)

- The PTC is a weird thing, it seems to be a temperature-sensitive conductor - when cold, it conducts, when hot it does not. When current flows through it, it gets hot. What this means is that when power is first applied, it shorts terminals 1 and 2 (also the Motor Run Capacitor) and power is applied to both windings of the compressor, allowing it to start. Once it gets hot (I assume this happens in seconds), power remains applied to only one winding, which is all the compressor needs to stay running at this time

- Once the PTC "unshorts" the Run Capacitor, the capacitor generates an off-phase kind of thing that I didn't bother to fully understand, I suspect it's about efficiency or not overdriving the motor when it's up to full speed.

- Pretty simple, right? So in my case, once I took off the Relay with the PTC/overload inside, I heard rattling of pieces in it, so I took it apart to discover chunks of a silverish coin-shaped item inside, it looked as if it had shattered, which it probably did after the 8 years of repeated cold/hot cycling and the jammed condenser motor experience of yesterday.

Diagnostics

Temperature Control

If your fridge is not cold enough and the Condenser Fan is not running, the problem is most likely in the temperature control wiring up above and not in anything down here. You'll need to take the temperature dial unit apart and do some probing there. Of course your fan may be shot, and you can check for 120V at the fan harness as well. If the fan is running, then most likely temp control system is fine.Compressor

It's a good idea to verify that the compressor is OK first: Use a multimeter (with everything unplugged!) and check resistance across each pair of pins on the compressor itself (3 combinations total). Two of your readings should be smaller than the third (the two have the same resistance on my fridge), and the third should be total of the two (see diagram, A-B goes through C). For example: 4ohm, 4ohm, 8ohm. If it's significantly off from this sum-total rule, you're probably about to buy a new fridge because the compressor windings are not feeling too good.

Additional note by HarryT below: You should also check that the windings are not shorted to chassis (either of the three pins)Overload

The relay unit has an overload component. If you're hearing buzzing for 5-10 seconds and then nothing, it's almost certainly doing it's job, but you can easily check that it's not open - simply use a meter to check between the blade terminal on the outside and the pin terminal on the inside of the unit (the one that the blue wire leads to). There should be continuity. In fact, there should be continuity between front and back on all 3 terminals - and this is why a lot of people first assume that the white box is nothing but a harness, when in fact it has the PTC relay and the Overload unit.PTC

Well, as I've already mentioned, if the relay box has stuff rattling in it, those are chunks of what used to be the PTC. However, with everything disconnected from the box and after it cools off, there should be some (considerable actually) continuity between terminals 1 and 2 (white and orange on my fridge). If it's fully open, the PTC is not functional, and the compressor can't start.Run Capacitor

Probably needs some electronic test tools to check, though I'm sure you can just apply DC (not AC, thanks Rick for your comment) to it for a bit, then measure voltage - the voltage should be slowly dropping. You could also just apply an Ohm-Meter to an uncharged capacitor and it should spike, then gradually drop. Mine is model JSU18X156AQA, though I suspect that anything that qualifies as a 15uF 10000AFC 180V+ would work.The Crisis

It became pretty clear that I need a new part, but it is now Sunday, stores are closed, and I have a fridge full of melting meat, fish, dairy, ravioli, and, most importantly - ice cream sandwiches! I can't eat them all, making this an emergency situation. Outside temperature was about 36°F at this point, making it ideal for fridge contents, but not freezer.The Hack

I did my research, came up with the above understanding of the diagram... and then there was only one thing left to try. See, if all that the broken part (PTC) is doing is shorting across the capacitor, then why not ... (OK remember the disclaimer? You blow yourself up - not my fault). So I loosened the terminals on the Run Capacitor so I could place a screwdriver across them, plugged in the fridge and while it was buzzing (overload about to disconnect a stalled compressor) I shorted across the terminals. (Yes my screwdriver is insulated, and yes I was holding my breath in fear). The spark was memorable, but the compressor started! All it took was about a 0.2 second arc short.

(Note also: in my reading, the literature warns that discharging the capacitor should be done via a minimum 1000Ohm high power resistor... clearly I skipped this step)

So what I have now is a fridge that will run until it reaches satisfactory temperature, at which point it will shut off until it gets warm enough to need to run again (which can be as long as hours). A this point it will revert to the "I can't start" state as before, until I short the capacitor again. This is fine with me because it maintains temperature fine for 12 hour periods - and I will hopefully receive the part tomorrow.Safety

I am not too comfortable entrusting my fire safety and the compressor's well-being to the overload unit, so I unplug the fridge once it gets cold and shuts off. Should the overload unit fail and get stuck closed, the compressor will be stalled indefinitely. Hopefully it'll all be over tomorrow.Update

The next day I got my replacement "Start Relay" kit (as the store called it), which contained similar but not identical looking parts. The kit cost me about $45. Everything mostly fit, except one of the capacitor blade terminals was smaller than on the original. Naturally I bent it loose and jammed it on, later realizing that the kit included a small-to-bigger blade terminal adapter (duh)... It's working fine, in fact it's been running great ever since (since 2009, and now it's 2016).

The fridge is so old that the plastic door handles yellowed and eroded, I wound up sanding and then painting them with krylon fusion (white), which looks pretty decent.

Help, I'm trying to get a fridge compressor to power an airbrush, i can get the thing running then it cuts out when the 60 psi is reached in the tank ( pressure cut out switch wired to mains input., but it takes about 3 minutes before it will run again any ideas what is driving this, i think it may be the cooling time for the ptc? This is the only decent explanation of how the starter system works that i have found trawling the net and if it does turn out to be the ptc any ideas how to get around it? Tim